Rotary Vane Vacuum Pumps 101: How They Work & Why They Matter

Oct 10, 2025

Rotary Vane Vacuum Pumps 101: How They Work & Why They Matter

08/19/2025

In the world of vacuum technology, there are only a few components that are as resourceful and widely used as the

rotary vane vacuum pump. From laboratories to industrial manufacturing lines, these devices silently power processes that rely on a controlled, reduced-pressure environment.

But how exactly do rotary vane vacuum pumps work, and why have they remained a core in so many industries for over a century? This article will explore the inner workings, applications and advantages of these essential machines.

What Is a Rotary Vane Vacuum Pump?

At its core, a rotary vane vacuum pump is a type of positive displacement pump. It works by trapping a volume of gas and mechanically reducing its volume to expel it from an exhaust port, creating a vacuum. The name “rotary vane” comes from the key design components: vanes mounted in a rotating rotor that moves inside a cavity.

This simple mechanism offers surprising power and consistency. Rotary vane pumps can achieve vacuum levels down to 0.1 millibar (mbar) or even lower in some oil-sealed configurations, making them suitable for a wide range of applications.

The Mechanics: How It Works

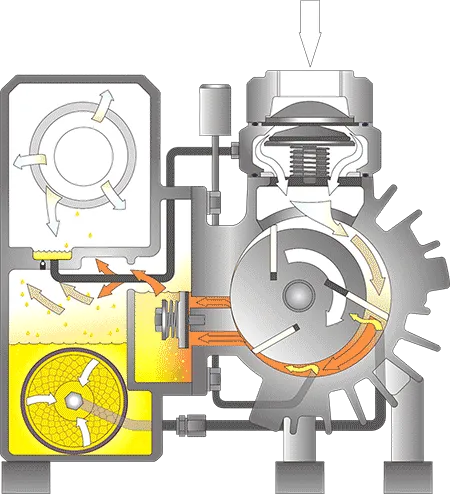

To understand how a rotary vane vacuum pump functions, it helps to picture its internal components:

- Cylindrical housing (stator): This is the stationary chamber inside which the pumping action occurs.

- Rotor: Offset from the center of the cylindrical housing, the rotor spins at high speed.

- Vaned blades: These typically slide freely in slots within the rotor, and they press outward against the housing walls due to centrifugal force.

- Inlet and outlet ports: These allow air or gas to enter and exit the pumping chamber.

Here is a simplified, step-by-step breakdown of what happens during one full rotation:

- As the rotor spins, the vanes extend outward, maintaining contact with the inner walls of the chamber.

- This action creates a series of variable-volume compartments between the rotor, the vanes and the stator.

- When a compartment aligns with the inlet port, it expands, drawing in gas from the application area (the vacuum chamber).

- As the rotor continues to spin, the compartment is sealed off from the inlet and its volume decreases.

- The trapped gas is compressed until it reaches the outlet port, where it is expelled against atmospheric pressure.

This process results in a steady suction at the inlet, creating and maintaining a vacuum in the connected system.

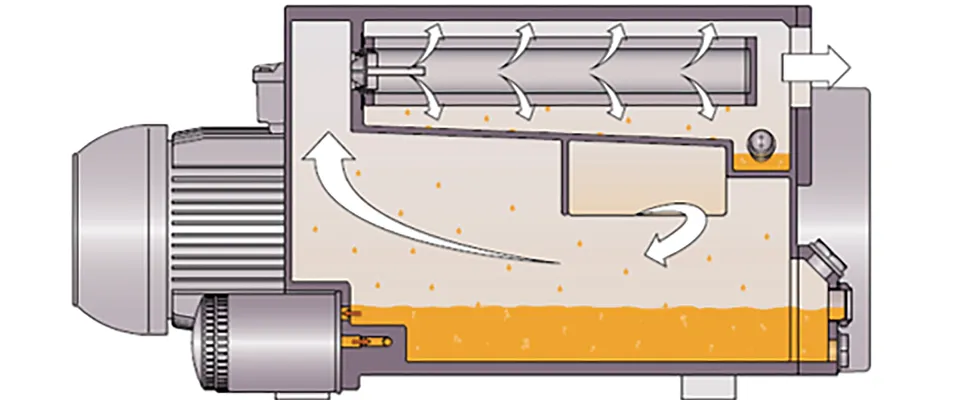

Oil-Sealed vs. Dry Rotary Vane Pumps

Rotary vane vacuum pumps come in two main types: oil-sealed and dry-running. Each has its own advantages.

Oil-Sealed Pumps

These are the most common type and are favored for their high vacuum performance and reliability. The oil serves several purposes

- Lubrication: Reduces friction and wear on moving parts

- Sealing: Improves the airtightness of the rotor-chamber interface

- Cooling: Dissipates heat generated during compression

- Corrosion protection: The oil coats internal components, shielding them from reactive or corrosive gases that might otherwise cause damage to metal surfaces.

The downside is that oil needs regular maintenance and can become contaminated if the pumped gas contains reactive or particulate matter.

Dry-Running Pumps

In dry rotary vane pumps, no oil enters the pumping chamber. Instead, materials such as carbon or high-grade plastics are used for the vanes, which require minimal lubrication. These are ideal for applications where oil contamination must be avoided, such as in pharmaceutical production or certain lab procedures. However, they typically do not reach as deep a vacuum as oil-sealed models and may wear faster in harsh environments.

Oil-sealed rotary vane pumps typically have lower upfront costs and are well-established for applications needing deep vacuum. However, they incur higher life cycle costs due to:

- Regular oil changes and disposal

- Maintenance of seals and filters

- Downtime from contamination or oil back streaming

Dry rotary vane pumps, while more expensive initially, often result in lower life cycle costs because they can:

- Eliminate oil-related maintenance and disposal

- Have fewer consumables

- Provide cleaner operation in sensitive environments

Applications Across Industries

Rotary vane vacuum pumps are universal because they offer a balance of performance, simplicity and cost-effectiveness. Here are just a few industries where they play a critical role:

- Laboratory and research: Used in vacuum ovens, freeze dryers, glove boxes and mass spectrometers

- Heat treating: Used for vacuum furnaces, oil quenching load lock chambers and degassing steps

- Medical and healthcare: Found in suction devices, sterilization systems and vacuum-assisted biopsy machines

- Food and beverage: Employed in vacuum packaging, degassing liquids and freeze drying

- Heating, ventilation and air conditioning (HVAC) and refrigeration: Used to evacuate air and moisture from systems before charging with refrigerant

- Automotive and aerospace: Vacuum forming of composite materials and leak testing components

Their ability to handle continuous operation and moderate gas loads makes them especially suited for semicontinuous and batch processes.

Between their mechanical design, balance of performance and cost and broad applicability of rotary vane vacuum pumps, they are a foundational technology in vacuum science.

Whether a user is a lab technician, a process engineer, or a maintenance worker, understanding the principles behind rotary vane pumps — and how they differ from other pump types like an ANSI pump or an Ebara pump — can give them a greater appreciation of the complex systems we often take for granted. In a world increasingly dependent on precise environments, from semiconductors to spacecraft, these simple pumps continue to prove that great things often start in a vacuum.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jan 27, 2026

Carbon-Graphite Blistering in Mechanical Seal Faces

Dec 09, 2025

6 Key Considerations When Selecting a New Pump

Nov 22, 2025

The Role of NSF 61-Certified Packing & Gaskets

Oct 14, 2025

Pump Requirements in Food & Beverage Manufacturing

Sep 29, 2025

Choosing the Right Pump for Deep Suction Lift