TS 109 Machined Mechanical Seal (Replace AESSEAL M01 , CRANE 109)

Our mechanical seal model 109 can replace AESSEAL M01 and john CRANE 109, which is widely used for industrial pumps. The normal material combination include resin carbon/ceramic/PTFE/ss304,resin carbon/tc/PTFE/ss304,sic/sic/PTFE/ss304 ,tc/tc/PTFE/ss304 and so on. we also can make changes as customers'requirement or totally design a new type of mechanical seal to meet clients'needs.

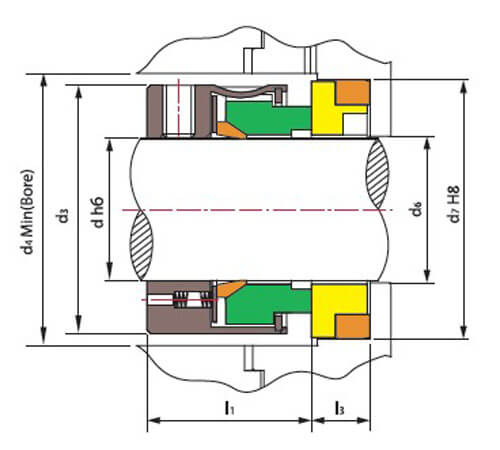

TS 109

Operating Limits :

|

Seal size |

d 3 |

d 4 |

d 6 |

d 7 |

l 1 |

l 3 |

|

0.500 |

26.7 |

29 |

13.4 |

25.40 |

20.6 |

7.95 |

|

0.625 |

30.7 |

34 |

16.6 |

31.75 |

19.0 |

10.3 |

|

0.750 |

34.0 |

37 |

19.7 |

34.93 |

22.2 |

10.3 |

|

0.875 |

37.2 |

40 |

22.9 |

38.10 |

23.8 |

10.3 |

|

1.000 |

40.3 |

43 |

26.1 |

41.28 |

25.4 |

11.1 |

|

1.125 |

43.5 |

46 |

29.4 |

44.45 |

27.0 |

11.1 |

|

1.250 |

48.3 |

51 |

32.4 |

47.63 |

27.0 |

11.1 |

|

1.375 |

51.5 |

54 |

35.6 |

50.80 |

28.6 |

11.1 |

|

1.500 |

54.6 |

58 |

38.8 |

53.98 |

28.6 |

11.1 |

|

1.625 |

61.0 |

64 |

42.4 |

60.33 |

35.0 |

12.7 |

|

1.750 |

64.2 |

67 |

45.5 |

63.50 |

35.0 |

12.7 |

|

1.875 |

67.3 |

70 |

48.7 |

66.68 |

35.0 |

12.7 |

|

2.000 |

70.5 |

73 |

51.9 |

69.85 |

35.0 |

12.7 |

|

2.125 |

76.9 |

80 |

55.0 |

76.20 |

43.0 |

14.3 |

|

2.250 |

80.0 |

83 |

58.2 |

79.38 |

43.0 |

14.3 |

|

2.375 |

83.2 |

86 |

61.4 |

82.55 |

43.0 |

14.3 |

|

2.500 |

86.4 |

89 |

64.6 |

85.73 |

43.0 |

14.6 |

|

2.625 |

89.6 |

92 |

67.7 |

85.73 |

43.0 |

15.9 |

|

2.750 |

92.7 |

96 |

70.9 |

88.90 |

43.0 |

15.9 |

|

2.875 |

95.9 |

99 |

74.1 |

85.25 |

43.0 |

15.9 |

|

3.000 |

97.5 |

100 |

77.3 |

98.43 |

43.0 |

15.9 |

|

3.125 |

100.7 |

104 |

80.5 |

101.60 |

43.0 |

19.8 |

|

3.250 |

105.4 |

108 |

83.6 |

104.78 |

43.0 |

19.8 |

|

3.375 |

108.6 |

111 |

86.8 |

107.95 |

43.0 |

19.8 |

|

3.500 |

111.8 |

115 |

90.0 |

111.13 |

43.0 |

19.8 |

|

3.625 |

115.0 |

118 |

93.1 |

114.30 |

43.0 |

19.8 |

|

3.750 |

118.1 |

121 |

96.3 |

117.48 |

43.0 |

19.8 |

|

3.875 |

121.3 |

124 |

99.5 |

120.65 |

43.0 |

19.8 |

|

4.000 |

124.5 |

127 |

102.7 |

123.83 |

43.0 |

19.8 |

|

4.125 |

127.7 |

131 |

106.3 |

130.18 |

43.0 |

19.8 |

|

4.250 |

130.8 |

134 |

109.5 |

133.35 |

43.0 |

19.8 |

|

4.375 |

134.0 |

137 |

112.7 |

136.53 |

43.0 |

19.8 |

|

4.500 |

137.2 |

140 |

115.9 |

139.70 |

43.0 |

19.8 |

|

4.625 |

149.9 |

153 |

119.0 |

142.88 |

51.0 |

19.8 |

|

4.750 |

153.1 |

156 |

122.2 |

146.05 |

51.0 |

19.8 |

|

4.875 |

156.2 |

159 |

125.4 |

149.23 |

51.0 |

19.8 |

|

5.000 |

159.4 |

165 |

128.6 |

152.40 |

51.0 |

19.8 |

|

5.125 |

162.6 |

168 |

131.7 |

155.58 |

51.0 |

19.8 |

|

5.250 |

165.8 |

172 |

134.9 |

158.75 |

51.0 |

19.8 |

|

5.375 |

168.9 |

175 |

138.1 |

161.93 |

51.0 |

19.8 |

|

5.500 |

172.1 |

178 |

141.3 |

165.10 |

51.0 |

19.8 |

|

5.625 |

175.3 |

181 |

\ |

\ |

51.0 |

\ |

|

5.750 |

178.5 |

184 |

\ |

\ |

51.0 |

\ |

|

5.875 |

181.6 |

187 |

\ |

\ |

51.0 |

\ |

|

6.000 |

184.8 |

191 |

\ |

\ |

51.0 |

\ |

.