TS (THERMOSIPHON SYSTEM)

TRISUN's thermosiphon system enables efficient, pump-free heat transfer using natural convection. Ideal for passive cooling in residential and industrial applications, it supports both open and closed-loop designs.

Thermosiphon System: A Passive Solution for Efficient Heat Transfer

The TRISUN thermosiphon system is an efficient method of passive heat transfer that relies on natural convection to circulate fluid without the need for a pump. In this system, heated water rises while cold water sinks, creating a continuous flow that enhances heat distribution. Heat pipes play a crucial role in transferring thermal energy, often working in conjunction with a heat sink to improve the cooling system's efficiency. The loop design allows water to circulate through an open-loop or closed-loop configuration, depending on the application. This makes it ideal for passive heat exchange in residential and industrial settings.

How TRISUN Thermosiphon System Improves Thermal Efficiency

One of the main benefits of the TRISUN system is its ability to optimize thermal efficiency in a wide range of applications. It is especially valuable in solar thermal systems and wood fire water heaters, where natural convection enables the continuous flow of heat without the need for mechanical pumps or complex mechanisms. The system's reliance on capillary action ensures that the heat transfer process is seamless, reducing the risk of mechanical failure and extending the lifespan of your heating or cooling system.

Benefits of Natural Convection

Natural convection allows the system to move heat without any external energy input, unlike traditional systems that require pumps or motors to circulate fluids. This results in lower operating costs and greater energy savings. By using ambient temperature gradients, the TRISUN system efficiently circulates heat, making it ideal for both residential and industrial heating needs.

Key Applications of TRISUN Thermosiphon System

The TRISUN system is versatile, with applications spanning across various industries and residential setups. Some key uses include:

1. Solar Thermal Systems

Sustainable Heating: By integrating these principles into solar thermal systems, users can harness solar energy more effectively, ensuring consistent hot water supply even without electrical power.

Low Maintenance: Since no pump is needed, the system is low-maintenance and operates efficiently, even in off-grid locations.

2. Wood Fire Water Heaters

Natural Circulation: This system provides efficient heat transfer from wood fire heaters to water tanks, ensuring a steady supply of hot water. This effect works with the natural heat from the fire, eliminating the need for electric pumps.

Eco-Friendly: The design reduces the carbon footprint by minimizing electricity usage while utilizing renewable heat sources.

Advantages of TRISUN THERMOSIPHON Systems for Residential and Industrial Use

|

Feature |

Description |

|

Energy-Efficient |

Operates without electricity or external energy sources, relying on natural fluid flow—significantly reduces energy costs. |

|

Low-Cost Operation & Maintenance |

Minimal wear and tear due to no moving parts like pumps—leads to lower maintenance costs, less downtime, and higher operational efficiency. |

|

Reliability & Durability |

Passive, self-regulating design ensures silent operation and minimal failure points—greatly enhances long-term reliability and system performance. |

How a Thermosiphon System Works?

A thermosiphon system operates using natural convection heat transfer to circulate fluid without pumps or electricity. When the fluid inside the system is heated, it becomes less dense and rises upward through the loop. As it releases heat and cools down, it becomes denser and flows back downward. This creates a continuous, self-sustaining circulation cycle.

In applications such as mechanical seal cooling, solar thermosiphon systems, and closed-loop thermal management, this passive circulation ensures reliable and energy-efficient performance. systems reduce maintenance requirements, lower operating costs, and improve system lifespan.

Comparison: Thermosiphon vs Pump-Driven Cooling Systems

A thermosiphon system offers significant advantages over traditional pump-driven cooling setups. The comparison below highlights key differences to help you understand which solution is best for your application.

Thermosiphon System (Natural Convection)

• Operates without electricity or pumps

• Simple and highly reliable due to fewer components

• Very low maintenance—no moving parts

• Excellent energy efficiency and long-term cost savings

• Ideal for API Plan 52 and 53A mechanical seal systems, solar heating, and off-grid applications

• Suitable for high-temperature, high-reliability environments

Pump-Driven Cooling System

• Requires continuous electrical power

• Higher system complexity with multiple mechanical components

• Increased maintenance due to pump wear, seal issues, and potential leaks

• Higher long-term operational and energy costs

• Better suited for systems requiring forced circulation in very large installations

For operations requiring dependable, cost-effective cooling, the thermosiphon system is often the preferred choice.

Installation Requirements & Operating Conditions

To ensure optimal performance and safety, these system must be installed according to the following guidelines:

Mounting Position

• The thermosiphon reservoir must be installed above the mechanical seal chamber.

• Maintain a height difference of at least 300–800 mm to allow natural convection circulation.

Piping Layout

• Use short, vertical piping runs wherever possible.

• Avoid excessive bends, long horizontal sections, or obstructions that restrict natural flow.

• Choose piping materials compatible with hot, abrasive, or chemically aggressive fluids.

Operating Temperature & Pressure

• Verify the system's rated operating limits:

o Temperature: 0–200°C (model-dependent)

o Pressure: up to 20–40 bar depending on the vessel

• Ensure compatibility with the selected barrier fluid.

Cooling & Ventilation

• Allow proper airflow around the thermosiphon tank or cooling coil.

• Keep the installation area free from dust and high ambient heat.

Fluid Selection

• Use recommended barrier fluids for mechanical seal support systems.

• For solar or heater applications, ensure water or glycol mixtures are suitable for high temperatures.

API Plan Compatibility

• API Plan 52: Unpressurized thermosiphon reservoir

• API Plan 53A: Pressurized thermosiphon reservoir

• API Plan 54: Auxiliary cooling system (pump-based)

Maintenance Guide for Thermosiphon Systems

Thermosiphon systems require minimal maintenance due to their passive, pump-free design. Regular inspection and fluid management ensure long-term reliability.

Routine Checks

• Inspect fluid levels through the sight glass periodically.

• Ensure there are no leaks from fittings, piping, or the reservoir.

Fluid Condition

• Check barrier fluid for contamination, discoloration, or particles.

• Refill or replace fluid as needed based on operating hours and system load.

Pressure & Temperature Monitoring

• Confirm the system remains within safe pressure and temperature limits.

• Ensure cooling coils and external surfaces are clean and exposed to adequate airflow.

Cooling Coil & External Surfaces

• Clean dust, dirt, and debris from cooling fins or coils to maintain heat dissipation efficiency.

Safety Components

• Inspect relief valves (if installed) annually.

• Check mounting brackets, gaskets, and fittings for wear.

Annual Maintenance

• Verify piping insulation integrity.

• Conduct a pressure test if required by site standards.

• Replace sealing components if signs of wear or degradation are present.

Common Troubleshooting

• Poor Circulation: Check height positioning and piping restrictions.

• Overheating: Improve cooling airflow or clean the coil.

• Low Fluid Level: Inspect for leaks and refill fluid.

• Foaming or Bubbles: Replace contaminated fluid.

With proper installation and simple periodic maintenance, this system delivers reliable, energy-efficient operation for many years.

Why Choose the TRISUN Thermosiphon System?

If you are considering enhancing your heating or cooling setup with a more sustainable solution, it offers numerous advantages. From its energy-efficient design to its low-maintenance nature, this system can be a game-changer for both residential and industrial applications. Whether you're looking to optimize your solar thermal systems or need an effective way to circulate heat in wood fire water heaters, the TRISUN system provides a reliable, cost-effective solution.

Frequently Asked Questions

Q1: What is the purpose of a thermosiphon system in mechanical seals?

ANS: This system is used to cool and lubricate double mechanical seals (typically in tandem or back-to-back configurations). It circulates barrier fluid between the seal chamber and an external reservoir, helping to dissipate heat, reduce friction, and prolong seal life in high-pressure or high-temperature applications.

Q2: Where is the TS-Thermosiphon System commonly used?

ANS: The TS System is ideal for use in pumps handling aggressive, hot, or abrasive media, especially in industries like:

• Chemical processing

• Oil and gas

• Power generation

• Pharmaceuticals

• Wastewater treatment

It supports API Plan 52, 53A, and 54 seal piping arrangements.

Q3: Does the TS-Thermosiphon System require an external power source?

ANS: No, This System operates on the natural convection principle (thermosiphon effect), requiring no external pump or power source for circulation. This makes it energy-efficient, low-maintenance, and reliable even in remote or unmanned installations.

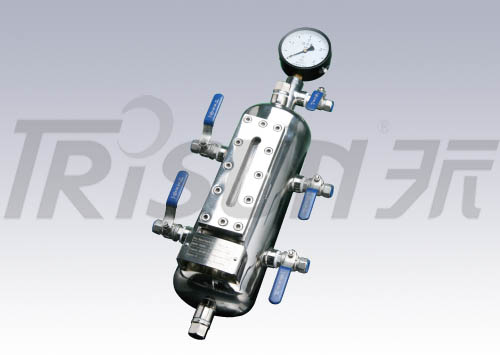

Q4: What are the key components included in the TS-Thermosiphon System?

ANS: The system typically includes:

• Stainless steel pressure vessel with sight glass

• Cooling coil or fins (optional)

• Pressure gauge and filling port

• Safety relief valve (optional)

• Level indicators and mounting brackets

All components are built to handle demanding industrial sealing environments and ensure safe operation.

Q5: How do I ensure compatibility between the TS-Thermosiphon System and my mechanical seal?

ANS: To ensure compatibility, consider the type of mechanical seal, piping plan, and operating conditions (pressure, temperature, fluid type). TRISUNLtd's experts can help you select or customize the TS System based on your specific sealing requirements, ensuring optimal performance and extended seal life.