TSDGS-J01 Dry Gas Seal

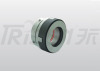

TRISUN's dry gas seals offer oil-free, high-efficiency sealing for centrifugal compressors using advanced spiral groove technology. Engineered for demanding industries, they reduce wear, enhance reliability, and eliminate contamination risks.

TSDGS-J01

High-Performance Dry Gas Seal Technology

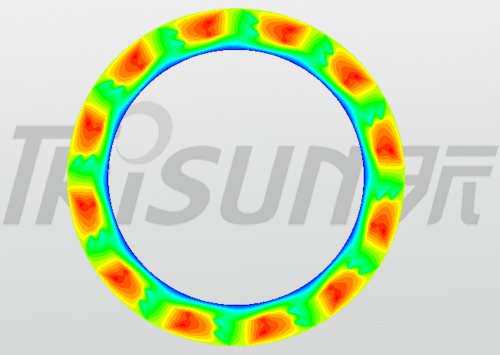

TRISUN's dry gas seal technology offers a high-performance sealing solution for centrifugal compressors, ensuring reliable operation without the need for traditional seal oil systems. Utilizing advanced spiral groove technology, these seals create a gas flowing film that reduces friction and wear, significantly improving efficiency and extending the lifespan of critical equipment. TRISUN's dry gas seal designs are engineered to meet the most demanding industrial requirements, providing exceptional sealing performance in high-speed and high-pressure applications.

Reliable Sealing Across Industrial Applications

TRISUN's dry gas seals provide superior sealing solutions for various industrial applications, including gas processing, petrochemicals, and power generation. By eliminating the need for seal oil, these seals enhance system reliability while reducing contamination risks. With precision-engineered spiral groove patterns, TRISUN ensures optimal gas film formation, improving compressor efficiency and reducing maintenance costs. Additionally, the incorporation of an intermediate labyrinth enhances sealing effectiveness, reducing leakage and ensuring stable performance in dynamic operating conditions.

Setting the Standard in Seal Technology

By leveraging innovative technology and high-quality materials, TRISUN continues to set industry standards in seal face optimization and dry gas seal solutions for critical industrial applications.

|

d |

4 minutes |

d 26 |

d 28 |

d 95 |

8 |

1 23 |

1 30 |

39 |

|

25 |

41 |

114 |

12 |

64.7 |

67.8 |

37.5 |

15.5 |

54.5 |

|

28 |

44 |

117 |

12 |

67.7 |

67.8 |

37.5 |

15.5 |

54.5 |

|

30 |

46 |

119 |

12 |

69.7 |

67.8 |

37.5 |

15.5 |

54.5 |

|

33 |

49 |

122 |

14 |

72.7 |

67.8 |

37.5 |

15.5 |

54.5 |

|

35 |

51 |

124 |

14 |

74.7 |

67.8 |

37.5 |

15.5 |

54.5 |

|

38 |

58 |

135 |

14 |

79.7 |

69.4 |

39.8 |

17.7 |

56.5 |

|

40 |

60 |

137 |

14 |

81.7 |

69.4 |

39.8 |

17.7 |

56.5 |

|

43 |

63 |

140 |

14 |

84.7 |

69.4 |

39.8 |

17.7 |

56.5 |

|

45 |

65 |

142 |

14 |

86.7 |

69.4 |

39.8 |

17.7 |

56.5 |

|

50 |

70 |

147 |

18 |

91.7 |

69.4 |

41.8 |

17.7 |

56.5 |

|

53 |

73 |

150 |

18 |

94.7 |

69.4 |

41.8 |

17.7 |

56.5 |

|

55 |

75 |

152 |

18 |

96.7 |

69.4 |

41.8 |

17.7 |

56.5 |

|

60 |

85 |

157 |

18 |

101.7 |

69.4 |

41.8 |

17.7 |

56.5 |

|

65 |

90 |

180 |

18 |

106.7 |

71.4 |

43.8 |

19.7 |

58.5 |

|

80 |

109 |

195 |

18 |

121.7 |

71.4 |

43.8 |

19.7 |

58.5 |

|

100 |

129 |

215 |

twenty two |

141.7 |

71.4 |

43.8 |

19.7 |

58.5 |

|

d |

4 minutes |

d 26 |

d 28 |

d 95 |

8 |

1 23 |

1 30 |

39 |

|

0.875 |

1.500 |

3.750 |

0.437 |

2.295 |

2.574 |

1.398 |

0.513 |

2.028 |

|

1.000 |

1.625 |

3.750 |

0.437 |

2.421 |

2.574 |

1.398 |

0.513 |

2.028 |

|

1.125 |

1.750 |

4.250 |

0.437 |

2.469 |

2.574 |

1.398 |

0.513 |

2.028 |

|

1.250 |

2.000 |

4.250 |

0.437 |

2.669 |

2.574 |

1.398 |

0.513 |

2.028 |

|

1.375* |

2.125 |

4.250 |

0.437 |

2.795 |

2.574 |

1.398 |

0.513 |

2.028 |

|

1.375^ |

2.000 |

4.250 |

0.437 |

2.795 |

2.574 |

1.398 |

0.513 |

2.028 |

|

1.500 |

2.250 |

4.875 |

0.562 |

3.142 |

2.732 |

1.567 |

0.697 |

2.224 |

|

1.625 |

2.375 |

4.500 |

0.437 |

2.680 |

2.732 |

1.567 |

0.697 |

2.224 |

|

1.750 |

2.500 |

5.500 |

0.562 |

3.390 |

2.732 |

1.567 |

0.697 |

2.224 |

|

1.875 |

2.625 |

5.500 |

0.562 |

3.335 |

2.732 |

1.567 |

0.697 |

2.224 |

|

2.000 |

2.750 |

4.750 |

0.562 |

3.461 |

2.732 |

1.567 |

0.697 |

2.224 |

|

2.125 |

2.875 |

6.000 |

0.687 |

3.768 |

2.732 |

1.567 |

0.697 |

2.224 |

|

2.250 |

3.125 |

6.500 |

0.687 |

3.890 |

2.732 |

1.567 |

0.697 |

2.224 |

|

2.375 |

3.250 |

6.250 |

0.687 |

4.016 |

2.732 |

1.567 |

0.697 |

2.224 |

|

2.500 |

3.375 |

6.500 |

0.687 |

4.142 |

2.812 |

1.724 |

0.776 |

2.303 |

|

2.625 |

3.625 |

6.500 |

0.687 |

4.268 |

2.812 |

1.724 |

0.776 |

2.303 |

|

2.750 |

3.750 |

7.000 |

0.687 |

4.370 |

2.812 |

1.724 |

0.776 |

2.303 |

|

3.000 |

4.000 |

7.000 |

0.687 |

4.642 |

2.812 |

1.724 |

0.776 |

2.303 |

|

3.500 |

4.500 |

7.250 |

0.812 |

5.142 |

2.812 |

1.724 |

0.776 |

2.303 |

|

4.000 |

5.000 |

7.250 |

0.812 |

5.642 |

2.812 |

1.724 |

0.776 |

2.303 |

TRISUN's dry gas seal technology offers a high-performance sealing solution for centrifugal compressors, ensuring reliable operation without the need for traditional seal oil systems. Utilizing advanced spiral groove technology, these seals create a gas flowing film that reduces friction and wear, significantly improving efficiency and extending the lifespan of critical equipment. TRISUN's dry gas seal designs are engineered to meet the most demanding industrial requirements, providing exceptional sealing performance in high-speed and high-pressure applications.

TRISUN's dry gas seals provide superior sealing solutions for various industrial applications, including gas processing, petrochemicals, and power generation. By eliminating the need for seal oil, these seals enhance system reliability while reducing contamination risks. With precision-engineered spiral groove patterns, TRISUN ensures optimal gas film formation, improving compressor efficiency and reducing maintenance costs. Additionally, the incorporation of an intermediate labyrinth enhances sealing effectiveness, reducing leakage and ensuring stable performance in dynamic operating conditions.

By leveraging innovative technology and high-quality materials, TRISUN continues to set industry standards in seal face optimization and dry gas seal solutions for critical industrial applications.