What Are Machined Seals and Why Are They Essential in Industrial Applications?

Feb 10, 2025

In the industrial landscape, trustworthiness is everything. Every piece of equipment, from chemical plants to automotive assembly lines, should work in concert for efficiency, safety, and productivity. At the heart of such dependability are machined seals and precision-engineered components designed to resist even the most demanding situations.

Let us understand these seals and why they are crucial for industrial applications. This article examines their role, benefits, and indispensableness to various industries.

Machined Seals – What are they?

These seals are custom sealing solutions made with advanced materials and manufacturing processes for specific performance in industrial equipment. Unlike the standard off-the-shelf seals, they perform under extreme conditions for unique needs.

They are essential in controlling the leakage of any fluid or gas in machinery to enhance efficiency during operation and protect equipment from wear and tear. Capable of functioning under fluctuating temperatures and pressures and with chemical exposure, they have become an essential component in industries dealing with chemical processing, power generation, water treatment, and automotive manufacturing.

Types of Machined Seals

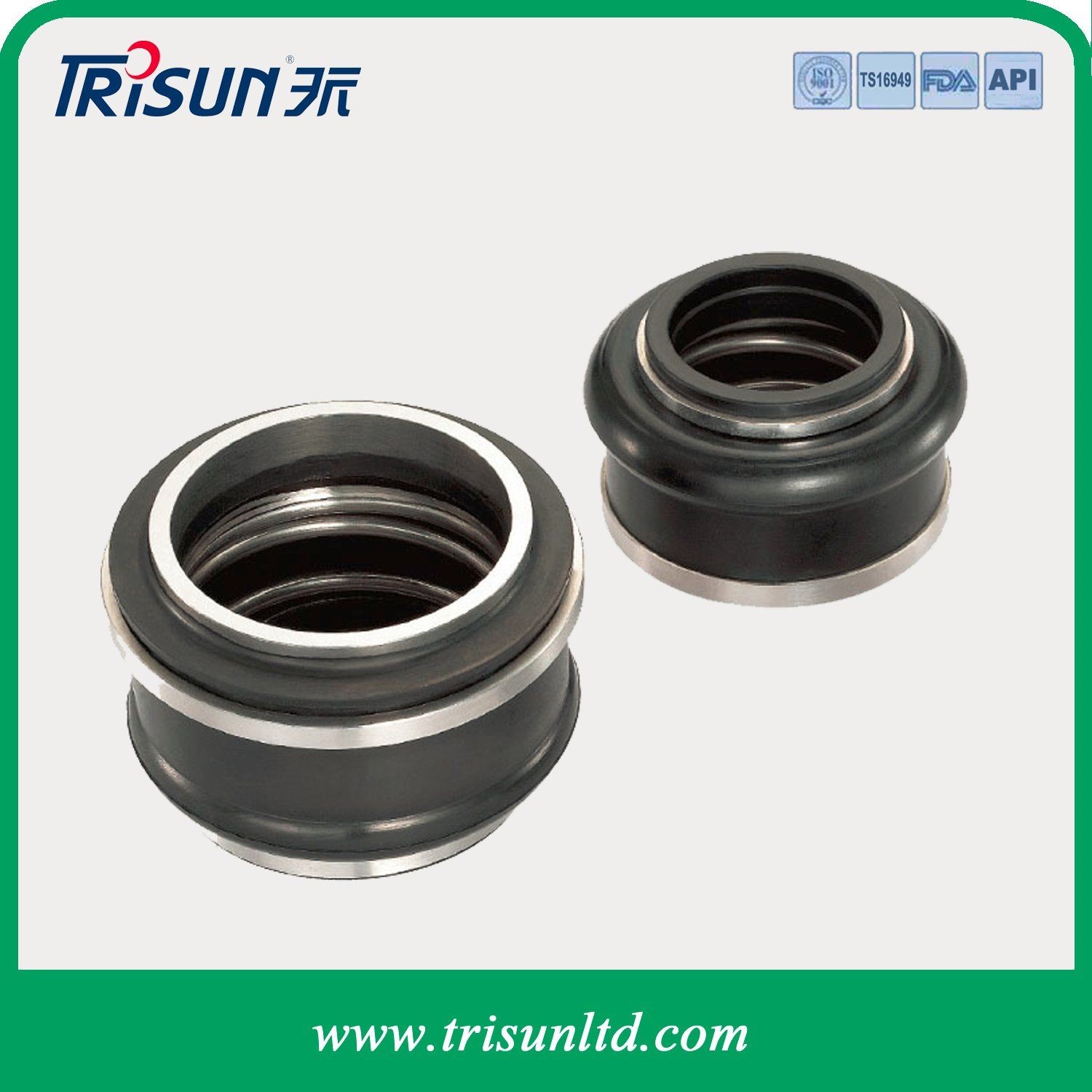

Machined seals are precision-engineered sealing solutions created using advanced CNC (Computer Numerical Control) machining technology. These seals can be customized to exact specifications, offering superior performance, durability, and compatibility for a wide range of applications. For the TS 58UR Machined Mechanical Seal, the machined design ensures accurate dimensions, consistent quality, and perfect fitting for FLYGT pump seal and mining industry applications.

Common Types of Machined Seals:

1. Face Seals

o Used in rotating equipment such as pumps and mixers.

o Provide a tight seal between the rotating and stationary parts to prevent leakage.

2. Lip Seals

o Used to retain lubrication and exclude contaminants.

o Ideal for high-speed rotating shafts.

3. O-Ring Seals

o Versatile sealing option for static and dynamic applications.

o Simple design but effective for pressure and temperature variations.

4. V-Ring Seals

o Elastomeric seals that protect against dirt, water, and other contaminants.

o Commonly used as secondary seals in mechanical seal assemblies.

5. Custom Profile Seals

o Designed to meet unique requirements for specific industries.

o Can be manufactured in special shapes and cross-sections for extreme conditions.

Machined Seal Material Comparison Table

|

Material |

Key Properties |

Advantages |

Common Applications |

|---|---|---|---|

|

Extremely hard and wear-resistant, high thermal conductivity, excellent chemical resistance |

Long service life, handles abrasive media, suitable for high-load conditions |

Mining pumps, slurry handling, chemical processing |

|

|

Resin Carbon |

Lightweight, self-lubricating, excellent chemical resistance |

Low friction, reduced energy consumption, corrosion-resistant |

Clean water pumps, light chemical processes |

|

Silicon Carbide (SiC) |

Hard, corrosion-resistant, high thermal shock resistance |

Excellent for high-temperature and aggressive chemical environments |

Oil & gas, chemical plants, high-temperature fluid sealing |

|

Viton® (FKM) |

Excellent chemical resistance, withstands high temperatures (-20°C to +200°C) |

Resistant to fuels, oils, and most chemicals, retains elasticity over time |

Pump secondary seals, petrochemical plants |

|

Nitrile Rubber (NBR) |

Good resistance to petroleum-based oils and fuels, low compression set |

Cost-effective, durable for moderate temperature applications |

General industrial sealing, water treatment plants |

|

PTFE (Teflon®) |

Exceptional chemical resistance, wide operating temperature range (-200°C to +260°C) |

Non-stick, low friction, suitable for aggressive chemicals and food-grade applications |

Pharmaceutical, food processing, corrosive chemical handling |

|

Stainless Steel (SUS304/SUS316) |

Corrosion-resistant, high strength, good machinability |

Withstands harsh environments, easy to maintain |

Pump springs, retainers, hardware for marine and chemical industry |

Why are machined seals one of the critical factors in industries?

Industrial equipment operates under extreme conditions, and their parts are often stretched to the breaking point.

Here's why they are such a key part of a successful operation:

- Minimizing Fluid and Gas Leaks

These seals are made to achieve tight sealing so that liquids and gases stay inside their respective systems. This is critical in industries such as chemical processing and pharmaceuticals, where minute leaks could mean big safety and operational concerns.

- Extending the Life of Equipment

Seals protect moving parts by reducing friction to prevent the buildup of contaminants in sensitive areas. This diminishes wear and tear, prolonging the apparatus's lifetime; thus, expensive, meager downtime decreases.

- Better Operational Efficiency

Where there are leakages in any system, the efficiency will always be compromised through reduced fluid, guarded pressure, or excessive energy use. A machined seal contributes to the conduction of most systems at an optimal level, resulting in better energy efficiency with more costs saved.

- Customization for Extremes of Temperature

While regular seals cannot withstand such extreme conditions, temperatures, hostile chemicals, or intense pressures, seals can. That is why they become very valuable in specialized applications, ranging from power plants to automotive systems.

- Regulatory Compliance

Such is the case for industries like food processing or pharmaceuticals, where strict requirements for seal safety and hygiene are implemented. Many of the machine seals have to be designed and certified against such rules and regulations to prevent any accidents that might occur with a view to the safety of both staff and the finished product.

Machined Seals in Application - An Overview across Industries

| Industry | Application of Machined Seals |

|---|---|

| Chemical and Pharmaceutical Industries | Machined seals resist chemical degradation when exposed to corrosive chemicals and volatile compounds, ensuring safety and reliability under extreme conditions. |

| Power Generation | Seals in power plants withstand high-pressure steam and fluids, contributing to system integrity and uninterrupted operation. |

| Automotive Manufacturing | Critical for engines, cooling systems, and fuel-efficient vehicles, these high-precision seals ensure reliability and meet strict performance standards. |

| Water Treatment Plants | These seals handle pressure fluctuations without contamination, offering long-lasting, maintenance-free performance in water treatment systems. |

Advantages of Machined Seals over Standard Seals

| Advantage | Description |

|---|---|

| Precision Fit | Designed to exact specifications for maximum performance. |

| Durability | Built to resist very adverse conditions and extended use. |

| Efficiency | Enhances system efficiency by minimizing leaks and preventing energy loss. |

| Customization | Offers tailored solutions to meet specific industry and application requirements, ensuring optimal compatibility and performance. |

Why Invest in High-Quality Machined Seals?

The proper seal can make all the difference in your application between smooth operations and costly failures. Besides, high-quality machined seals contribute to the efficiency and safety of industrial equipment, thus contributing to long-term cost savings by minimizing downtime and reducing maintenance requirements.

When investing in machined seals, it's essential to work with a provider who understands your industry's unique challenges and can deliver solutions to meet your specific needs.

Common Seal Challenges and How Machined Seals Solve Them

Industrial equipment often operates under harsh conditions—extreme pressure, high rotational speeds, aggressive chemicals, or abrasive slurries. These environments can degrade sealing components quickly if not engineered precisely. Below are some of the most common sealing problems—and how machined seals effectively resolve them.

| Issue | Problem | Solution |

|---|---|---|

| 1. Leakage Due to Misalignment or Wear | Shaft misalignment, excessive vibration, or poorly matched seal faces can lead to leakage—one of the most frequent and costly problems in pumps, compressors, and turbines. | Machined seals are custom-engineered to match exact shaft tolerances and housing geometries. Precision manufacturing ensures tighter sealing tolerances and improved surface finishes, reducing the likelihood of leakage and extending operational uptime. |

| 2. O-Ring Extrusion or Deterioration | In high-pressure applications, standard elastomeric O-rings can extrude into gaps or degrade under chemical attack. | Machined PTFE, FFKM, or PEEK seals offer superior chemical resistance and high-pressure stability. They are designed with optimized gland geometries to eliminate extrusion paths and resist thermal cycling, making them ideal for aggressive industrial fluids. |

| 3. Shaft Deflection at High Speeds | At high RPMs, centrifugal force and fluid turbulence cause shaft deflection, leading to uneven wear or seal failure. | Machined seals use balanced face designs and are often paired with floating bushings or hydrodynamic faces. These reduce friction and compensate for slight shaft movement, maintaining consistent contact and performance. |

Trends & Innovations in Machined Seal Technology

As industries demand more reliable and efficient rotating equipment, seal manufacturers are evolving rapidly. Below are key innovations transforming the machined seal landscape:

1. Laser-Etched Surface Textures

Advanced laser technology now allows microscopic grooves to be etched on sealing surfaces. These textures can:

Promote hydrodynamic lift for reduced wear

Improve lubrication film stability

Minimize friction at startup

This enhances performance under dry-running or high-speed conditions—especially in food, pharma, or vacuum environments where conventional lubricants are limited.

2. Piezoelectric-Responsive Seals

In cutting-edge research and aerospace sectors, piezoelectric materials are being explored in seals that adjust their shape dynamically in response to changes in pressure or temperature. These adaptive seals can:

Minimize leakage during pressure fluctuations

Compensate for thermal expansion in real time

While not yet widespread, they indicate a major shift toward intelligent sealing systems.

3. Hydrodynamic Lift Face Designs

Seals with patented groove profiles create a micro-thin fluid film during rotation—lifting the seal faces slightly to reduce friction and heat buildup. These designs extend seal life and are ideal for:

High-speed pumps

Compressors

Clean-in-place (CIP) equipment

Hydrodynamic seals are now commonly used in energy-efficient systems and equipment that require minimal maintenance over long duty cycles.

Why Choose TRISUN for Machined Seals?

Selecting the right sealing partner is just as important as selecting the seal itself. TRISUN stands out as a trusted manufacturer of high-performance machined seals, offering unmatched expertise, precision, and reliability.

Key Reasons to Choose TRISUN:

• Proven Industry Experience – With decades of sealing expertise, TRISUN serves industries including oil & gas, chemical processing, pharmaceuticals, food & beverage, water treatment, and power generation.

• Custom Engineering – Every application has unique requirements. TRISUN designs and manufactures seals to match exact dimensions, operating conditions, and regulatory standards.

• Wide Material Portfolio – From PTFE, PEEK, and polyurethane to FDA- and USP Class VI–approved elastomers, TRISUN provides materials tailored for demanding environments.

• Fast Prototyping & Short Lead Times – On-demand CNC machining enables rapid turnaround, reducing downtime and inventory costs.

• Global Quality Standards – TRISUN machined seals comply with ISO, FDA, and other international certifications, ensuring safety and performance.

• Innovative Technology – Leveraging advanced machining, digital design, and hybrid sealing technologies, TRISUN continuously pushes sealing performance to new levels.

• Dedicated Support – Expert application engineers provide technical guidance, troubleshooting, and after-sales service to maximize equipment uptime.

Choosing TRISUN for machined seals means choosing reliability, customization, and long-term performance in the most critical applications.

Frequently Asked Questions About Machined Seals

Q1: How are machined seals different from molded seals?

Ans: These seals are precisely cut from engineered materials using CNC or lathe machines, allowing for customization in dimensions, profiles, and tolerances. In contrast, molded seals are mass-produced using pre-designed molds, making them less flexible for unique or complex applications. These are ideal for low-volume, high-performance, or quick-turn requirements, while molded seals suit high-volume, standard applications.

Q2: What materials are used in high-performance sealing applications?

Ans: High-performance machined seals are made from advanced materials that offer excellent resistance to pressure, temperature, chemicals, and wear. Common materials include:

• PTFE (Teflon) – Chemical-resistant and low-friction

• FFKM (Perfluoroelastomer) – High thermal and chemical stability

• PEEK – Excellent mechanical strength and dimensional stability

• HNBR, FKM (Viton), EPDM – Elastomers for dynamic and static applications

Material choice depends on the application environment—pressure, temperature, chemical exposure, and regulatory requirements.

Q3: How long do machined seals typically last?

Ans: The lifespan of a seal depends on its operating conditions and material composition. In ideal conditions, machined seals can last 2 to 5 times longer than standard off-the-shelf seals. With proper installation and maintenance, they offer extended service intervals, reducing downtime and total cost of ownership across industries like power generation, oil & gas, and chemical processing.

Q4: Can I get FDA-compliant or food-grade machined seals?

Ans: Yes, TRISUNLtd offers FDA-approved and food-grade machined seals specifically designed for use in food processing, beverage, pharmaceutical, and biotechnology industries. These seals are manufactured from compliant materials such as PTFE, EPDM, and silicone, and meet stringent regulatory standards like FDA 21 CFR, USP Class VI, and EU 1935/2004 to ensure hygiene, safety, and non-contamination.

Q5: How does TRISUN ensure quality control in its seal production?

Ans: TRISUN follows a rigorous quality control process that includes:

• Material certification for traceability and performance

• Precision CNC machining for dimensional accuracy

• In-house testing for pressure, temperature, and chemical resistance

• ISO 9001-certified manufacturing standards

Additionally, each seal is inspected for tolerances, surface finish, and geometry to guarantee reliability and performance in the most demanding industrial environments.

Final Thoughts

A machined seal is more than just a component—it's the unsung hero behind countless operations, silently ensuring machinery performs at its best. Whether you're in the chemical industry dealing with aggressive fluids, in automotive manufacturing requiring tight tolerances, or in power generation where pressure extremes are the norm, the right seal can make or break your efficiency.

Precision-engineered seals, pump sleeves, and critical pump parts play a pivotal role in reducing downtime, lowering maintenance costs, and ensuring safety compliance across sectors. In water treatment facilities, they prevent contamination and leakage. In pharmaceutical manufacturing, they help maintain sterile environments. No matter the application, the right seal is not just about durability—it's about reliability, safety, and performance under pressure.

What sets these seals apart is their customizability. Unlike standard off-the-shelf seals, These seals are tailored to your exact specifications, making them ideal for unique environments, high-stakes industries, and equipment that demands uncompromising performance.

Why settle for less when you can have sealing solutions engineered for excellence?

- Improve operational efficiency

- Ensure regulatory compliance

- Extend equipment lifespan

- Minimize maintenance and unplanned downtime

At TRISUNLtd, we specialize in delivering advanced sealing technologies tailored to your application—no matter how complex or demanding. From design to delivery, our experts collaborate closely with you to ensure your seal fits perfectly, performs optimally, and lasts longer.

Ready to optimize your operations with a customized machined seal for your specific needs?

Contact TRISUNLtd today to discover how our precision-engineered sealing solutions can elevate your industrial performance and give you a lasting competitive edge. Let's seal your success—one high-performance component at a time.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor