Lapping machine

High-Precision Lapping Machine

or Industrial Applications

A lapping machine is an essential precision tool used to achieve flat, smooth, and polished surfaces in manufacturing. Designed for industries that demand exact tolerances, our machine ensures consistent quality and reduces rework. Whether you are in automotive, aerospace, or toolmaking, this lapping machine delivers unmatched accuracy and efficiency.

Features & Benefits

Key Features

- Precision Surface Finishing – Achieves high flatness and surface smoothness for critical components.

- Durable Build Quality – Constructed with heavy-duty materials for long-lasting performance.

- Variable Speed Control – Adjustable speed settings for different materials and applications.

- User-Friendly Design – Easy operation with intuitive controls for operators of all skill levels.

- Consistent Results – Delivers uniform surface finishes, minimizing material wastage.

- Low Maintenance – Designed with fewer wear-prone parts to reduce downtime.

- Customizable Options – Available in different sizes and specifications to suit specific industry needs.

Benefits

- Increases accuracy and reduces part rejection.

- Improves efficiency with faster finishing cycles.

- Extends the lifespan of critical machine parts.

- Lowers operational costs by reducing rework.

- Adaptable across multiple industries and materials.

Why Choose This Product

✅ ISO-certified quality

✅ Proven industry applications

✅ Backed by expert support

How It Works / Usage Guide

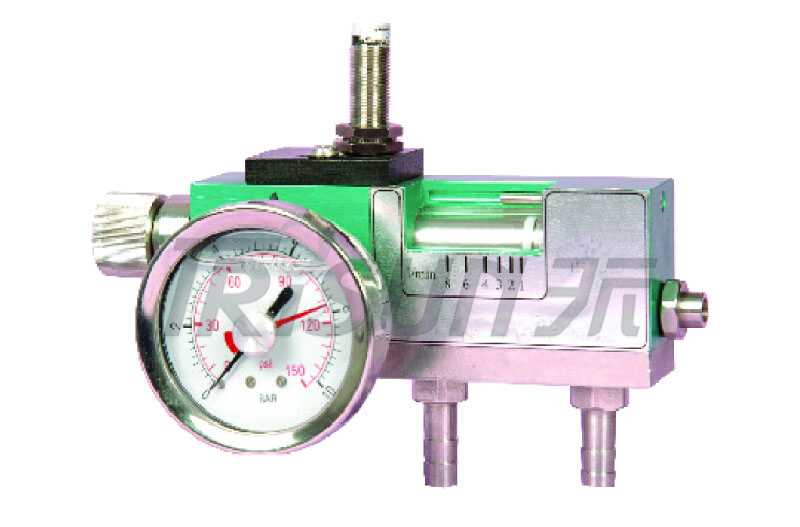

- Set Up the Machine – Install the workpiece and choose the right abrasive slurry.

- Adjust Settings – Select speed and pressure based on material type.

- Start Lapping Process – Operate the machine to achieve the required flatness.

- Inspect & Finish – Measure the surface quality and repeat if necessary.

Industry Applications of Lapping Machine

- Automotive Industry – Engine components, fuel systems, and valve seats.

- Aerospace Industry – High-precision turbine blades and sealing surfaces.

- Tool & Die Making – Dies, molds, and cutting tools requiring exact tolerances.

- Electronics Manufacturing – Flat surfaces for semiconductors and micro-components.

- Medical Devices – Surgical instruments and precision implants.

- Energy Sector – Sealing components in turbines and pumps.

Customer Reviews / Testimonials

Ravi M., Automotive Engineer

"The lapping machine improved our production accuracy by 40%. Consistent results every time."

Elena K., Aerospace Manufacturer

"We needed extreme precision, and this machine delivered. Reliable and easy to use."

Michael T., Toolmaking Supervisor

"Low maintenance and robust build. Perfect investment for our workshop."

Frequently Asked Questions (FAQs)

A1: A lapping machine is used to achieve flat, smooth, and polished surfaces.

It enhances accuracy in components like valves, blades, and dies.

It ensures precision and efficiency in industrial applications.

Q2: How does a lapping machine work?

A2: The machine uses abrasive slurry between the workpiece and lapping plate.

Controlled pressure and motion remove material evenly.

This produces a uniform, flat, and polished surface.

Q3: Which industries use lapping machines?

A3: Lapping machines are used in automotive, aerospace, toolmaking, and electronics.

They are vital in medical and energy equipment production.

Any industry requiring precision finishing relies on lapping machines.

Q4: What materials can be lapped?

A4: Metals, ceramics, plastics, and composite materials can be lapped.

Each requires suitable abrasives and speed settings.

The process adapts to different hardness levels and tolerances.

Q5: Are lapping machines expensive to maintain?

A5: No, they are designed for low maintenance.

Proper cleaning and periodic checks ensure long life.

Wear parts are minimal and easily replaceable.

Q6: Can lapping machines be customized?

A6: Yes, they are available in multiple sizes and configurations.

Custom designs are available for unique industry needs.

This ensures efficiency and compatibility with specific applications.