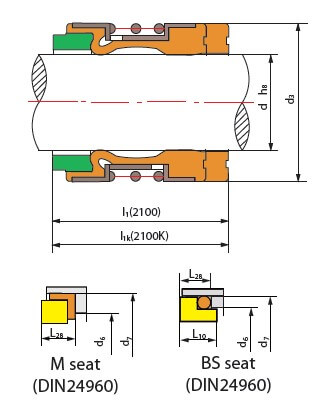

TS 2100 Machined Mechanical Seal (replace AESSEAL B05,Crane 2100 and FLOWSERVE 140)

we usually us seat type G6 for match it. The normal material combination include carbon/ceramic/nbr/

ss304,resin carbon/ceramic/nbr/ss304/,sic/sic/nbr/ss304,tc/tc/nbr/ss316 and so on. we also can make

changes as customers'requirement or totally totally design a new type of mechanical seal to meet clients'needs.

Pressure: ≤1.6MPa

|

Seal size d(mm) |

d3 |

d6 |

d7 |

2100 |

2100K |

M seat |

BS seat |

|

l1 |

l1k |

l28 |

l10 |

||||

|

10 |

20 |

17 |

21 |

15 |

27.5 |

5 |

6.0 |

|

12 |

22 |

19 |

23 |

15 |

26.5 |

6 |

6.8 |

|

14 |

24 |

21 |

25 |

15 |

29.0 |

6 |

6.8 |

|

15 |

25 |

22 |

26 |

15 |

29.0 |

6 |

6.8 |

|

16 |

26 |

23 |

27 |

15 |

29.0 |

6 |

6.8 |

|

18 |

32 |

27 |

33 |

20 |

31.5 |

6 |

7.0 |

|

20 |

34 |

29 |

35 |

20 |

31.5 |

6 |

7.0 |

|

22 |

36 |

31 |

37 |

20 |

31.5 |

6 |

7.0 |

|

24 |

38 |

33 |

39 |

20 |

34.0 |

6 |

7.0 |

|

25 |

39 |

34 |

40 |

20 |

34.0 |

6 |

7.0 |

|

28 |

42 |

37 |

43 |

26 |

36.5 |

6 |

7.0 |

|

30 |

44 |

39 |

45 |

26 |

35.5 |

7 |

8.0 |

|

32 |

46 |

42 |

48 |

26 |

35.5 |

7 |

8.0 |

|

33 |

47 |

42 |

48 |

26 |

35.5 |

7 |

8.0 |

|

35 |

49 |

44 |

50 |

26 |

34.5 |

8 |

9.0 |

|

38 |

54 |

49 |

56 |

30 |

37.0 |

8 |

9.0 |

|

40 |

56 |

51 |

58 |

30 |

37.0 |

8 |

9.0 |

|

43 |

59 |

54 |

61 |

30 |

37.0 |

8 |

9.0 |

|

45 |

61 |

56 |

63 |

30 |

37.0 |

8 |

9.0 |

|

48 |

64 |

59 |

66 |

30 |

35.0 |

10 |

11.0 |

|

50 |

66 |

62 |

70 |

30 |

37.5 |

10 |

11.0 |

|

53 |

69 |

65 |

73 |

30 |

37.5 |

10 |

11.0 |

|

55 |

71 |

67 |

75 |

30 |

37.5 |

10 |

11.0 |

|

60 |

80 |

72 |

80 |

33 |

40.5 |

12 |

12.7 |

|

65 |

85 |

77 |

85 |

33 |

40.5 |

12 |

12.7 |

|

70 |

90 |

83 |

92 |

33 |

48.0 |

12 |

12.7 |

|

75 |

99 |

88 |

97 |

40 |

48.0 |

12 |

12.7 |

.