TS MG1 Machined Mechanical Seal (replace AESSEAL B02,BURGMANN MG1,FLOWSERVE 190,MTU FG1;for Hecker HN 410SU) TS MG12(replace AESSEAL B012,BURGMANN MG12,FLOWSERVE 192, MTU FG2;for Hecker HN 410KU)

The TS‑MG1 mechanical seal by TRISUN is a high-quality replacement for Burgmann mechanical seals, offering excellent durability, leak resistance, and easy installation. Ideal for pumps in industrial and chemical applications.

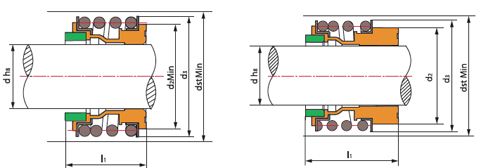

Our Mechanical seal model MG12 can Replace Replace AESSEAL B012, BURGMANN MG12 , FLOWSERVE 192 and MTU FG2 , which is widely used for Hecker HN 410KU and other kinds of pumps . we usually have 4 types of stationary seat for customer's choice,G4,G6,G60 and G9. The normal material combination include carbon/ceramic/nbr/ss304,resin carbon/ceramic/nbr/ss304/,sic/sic/nbr/ss304,tc/tc/nbr/ss316 and so on. we also can make changes as customers'requirement or totally design a new type of mechanical seal to meet clients'needs.

TS MG1(TSG) TS MG12(TSG2)

Reliable Burgmann Mechanical Seal Solutions

TRISUN's Burgmann mechanical seal solutions are engineered to meet the rigorous demands of the process industry, providing dependable sealing for a wide range of industrial applications. These seals ensure durability, efficiency, and compatibility with harsh operating conditions where high-performance sealing is critical.

High-Quality Alternative to Eagle Burgmann

Offering advanced sealing technology, TRISUN delivers high-quality Burgmann mechanical seal replacements that serve as reliable alternatives to well-known brands like Eagle Burgmann. These seals help maintain equipment integrity while boosting operational efficiency.

Precision Engineered for Industrial Applications

Manufactured with precision engineering, TRISUN's Burgmann mechanical seal replacements excel in pumps and rotating equipment subjected to high pressures and extreme environments. Their robust design minimizes downtime and lowers maintenance costs, reinforcing TRISUN's leadership in industrial sealing innovation.

Custom Sealing Solutions for Diverse Industries

TRISUN understands that every industry has unique sealing requirements. That's why their Burgmann mechanical seal replacements are available in a wide range of configurations, materials, and sizes to suit applications across sectors such as chemical processing, power generation, pharmaceuticals, and water treatment. Whether it's handling aggressive chemicals, abrasive slurries, or high-temperature fluids, TRISUN's customized seal solutions deliver maximum reliability and performance.

Compatibility and Easy Integration

Engineered for seamless compatibility, TRISUN's mechanical seals can be directly fitted into equipment originally designed for Eagle Burgmann seals, making replacements hassle-free and cost-effective. This drop-in compatibility ensures minimal downtime during installation or maintenance, helping businesses maintain productivity without expensive modifications to existing systems. TRISUN also provides detailed technical support to assist with proper selection and installation.

Quality Assurance and Global Support

Every TRISUN Burgmann replacement seal undergoes stringent quality testing to ensure it meets or exceeds international standards. Backed by ISO-certified manufacturing and a team of sealing experts, TRISUN guarantees performance you can trust. Their global network and responsive customer service team ensure that businesses receive timely support, spare parts, and troubleshooting whenever needed—reinforcing TRISUN as a trusted partner for critical sealing solutions worldwide.

Installation & Maintenance Guide for TS MG1 Burgmann Mechanical Seal

The TS MG1 Mechanical Seal by TRISUN is a high-quality replacement for Burgmann MG1 seals, offering excellent durability, leak resistance, and easy installation. Ideal for pumps in industrial and chemical applications.

Installation Instructions

1. Preparation

o Safety First: Ensure the pump is powered off and properly isolated.

o Cleanliness: Clean the shaft and seal chamber to remove any debris or old sealant.

2. Seal Inspection

o Visual Check: Inspect the TS MG1 Mechanical Seal for any visible damage.

o Component Verification: Ensure all parts are present and match the specifications.

3. Lubrication

o Apply Lubricant: Lightly lubricate the shaft and seal faces with an appropriate lubricant to facilitate smooth installation.

4. Seal Installation

o Positioning: Carefully align the seal onto the shaft, ensuring the seal faces are not damaged.

o Assembly: Slide the seal into the seal chamber, ensuring it sits evenly without forcing.

5. Reassembly

o Gland Tightening: Reassemble the gland and tighten evenly to the manufacturer's specifications.

o Rotation Check: Manually rotate the shaft to ensure smooth operation.

Maintenance Tips

· Regular Inspection: Periodically inspect the TS MG1 Mechanical Seal for signs of wear or damage.

· Leak Monitoring: Check for any leaks around the seal area and address promptly.

· Lubrication: Ensure the seal faces are adequately lubricated to prevent dry running.

· Replacement: Replace the seal if any component shows signs of significant wear or damage.

FAQs

1. Which pumps are compatible with the TS-MG1 Burgmann mechanical seal replacement?

The TS-MG1 fits pumps like Hecker HN 410SU, KSB pumps, and other industrial pumps using MG1-style seals.

2. What are the operating limits of the TS-MG1 Burgmann mechanical seal?

It operates at pressures up to 1.2 MPa, speeds up to 10 m/s, and temperatures from –20 °C to +120 °C.

3. What materials are used in the TS-MG1 mechanical seal?

Stationary ring: Ceramic, SiC, or TC; rotary ring: carbon or SiC; secondary seals: NBR, EPDM, or Viton; springs/parts: stainless steel.

4. How do I select the correct size for the TS-MG1 mechanical seal?

Available in multiple sizes (10 mm, 20 mm, 25 mm, 30 mm, 50 mm). Verify your pump shaft diameter to ensure a proper fit.

5. What are the benefits of using the TS-MG1 mechanical seal?

Durable, leak-resistant, easy to install, and a cost-effective alternative to Burgmann mechanical seals, reducing downtime while ensuring reliable performance.