TS X Machined Mechanical Seal (for FLYGT PUMP)

Looking for a reliable Flygt pump seal replacement? Our TS-X machined mechanical seals are fully compatible with Flygt submersible pump models including N 3090, N 3100, NP 3120, NP 3150, N 3170, and N 3200. Designed for wastewater and demanding industrial environments, these seals ensure long-lasting performance, leak prevention, and reduced downtime.

Our

Mechanical

seal

model

X

Reliable FLYGT Pump Seal Replacement for Industrial Use

When it comes to maintaining the performance of submersible pumps, a high-quality FLYGT pump seal is essential. The TS-X Machined Mechanical Seal is designed specifically for FLYGT pumps, offering unmatched sealing reliability even under harsh operating conditions. Whether you're dealing with wastewater, sludge, or other aggressive fluids, this seal ensures consistent performance and leak prevention.

Precision Engineering for Long-Lasting Durability

The TS-X Machined Mechanical Seal is built using advanced manufacturing processes and premium-grade materials to meet the exacting demands of FLYGT pump systems. Its custom-machined design guarantees a perfect fit, minimizing wear and reducing the risk of system failure. This precision engineering helps extend pump life, reduce maintenance costs, and improve overall operational efficiency.

Perfect Fit for FLYGT Pump Models

Unlike generic alternatives, the TS-X seal is tailored to match the specifications of FLYGT pump models, ensuring seamless installation and optimal sealing performance. Whether you're replacing a worn-out FLYGT pump seal or upgrading your current system, the TS-X provides a dependable solution for industrial facilities, municipal plants, and wastewater treatment operations.

Why Choose TS-X for Your FLYGT Pump Seal Needs

Choosing the TS-X Machined Mechanical Seal means investing in performance, reliability, and long-term value. It's engineered to withstand extreme temperatures, abrasive fluids, and continuous operation—making it an ideal FLYGT pump seal replacement for high-demand environments. Ensure minimal downtime and maximum productivity with a sealing solution trusted by industry professionals.

Compatibility Table – TS-X Seal Sizes by FLYGT Pump Model

|

FLYGT Pump Model |

TS-X Seal Size (mm) |

Shaft Diameter (mm) |

|

FLYGT N 3090 |

20 |

20 |

|

FLYGT N 3100 |

twenty two |

twenty two |

|

FLYGT NP 3120 |

25 |

25 |

|

FLYGT NP 3150 |

28 |

28 |

|

FLYGT N 3170 |

30 |

30 |

|

FLYGT N 3200 |

35 |

35 |

Note: Always verify pump model and shaft size before ordering to ensure optimal fit and performance.

Applications

TS-X mechanical seals are ideal for a wide range of industrial applications:

· Municipal wastewater plants – reliable seal for continuous operation

· Food & beverage processing – corrosion-resistant materials for hygiene compliance

· Mining and slurry handling – handles abrasive fluids and harsh conditions

· Chemical processing – compatible with aggressive chemicals

· Industrial water treatment – ensures leak-free pumping and long service life

Comparison & Buyer Guidance

TS-X vs Generic Pump Seals

|

Feature |

TS-X Seal |

Generic Seal |

|

Lifespan |

3–5 years |

1–2 years |

|

Fit Accuracy |

Perfect fit for FLYGT |

Often generic, may need adjustments |

|

Leak Resistance |

High |

Moderate |

|

Cost-Effectiveness |

Reduces maintenance & downtime |

Lower initial cost, higher long-term cost |

|

Material Quality |

Premium-grade SiC/TC |

Standard materials |

How to Choose the Right FLYGT Pump Seal

1. Check Shaft Size – Match the TS-X seal to your pump's shaft diameter.

2. Identify Fluid Type – Ensure the seal materials are compatible with the pumped medium.

3. Consider Operating Temperature & Pressure – TS-X supports –30 °C to 200 °C and pressures up to 1 MPa.

4. Select Seal Size – Choose from TS-X sizes 20mm, 22mm, 25mm, 28mm, 30mm, or 35mm for optimal fit.

Installation & Maintenance Tips for TS X Machined Mechanical Seal (for FLYGT PUMP Seal)

Best Practices for Installing a TS-X FLYGT Pump Seal:

· Ensure the shaft and seal housing are clean and free of debris.

· Lubricate the seal faces lightly before installation.

· Install carefully to avoid misalignment.

· Check O-rings and springs for damage before assembly.

· After installation, monitor pump for vibration or leakage.

Ready to upgrade your FLYGT pump performance? Contact TrisunLtd today for quick pricing, expert guidance, and fast global delivery.

FAQs

1. What are the performance specifications of the TS-X mechanical seal?

The TS-X mechanical seal supports operating pressures up to 1 MPa, maximum shaft speeds of 5 m/s, and a wide temperature range from –30 °C to +200 °C, making it suitable for demanding submersible pump applications.

2. Which materials are used in the construction of the TS-X mechanical seal?

The TS-X seal features a rotary ring and stationary ring made from Silicon Carbide (SiC) or Tungsten Carbide (TC) for superior wear resistance. O-rings are available in NBR, EPDM, or Viton, while springs are manufactured from SUS304 or SUS316 stainless steel. The spring cover and retainer are constructed from Bakelite or Alumina, ensuring durability in harsh operating conditions.

3. Is the TS-X mechanical seal specifically designed for Flygt pump seal replacement?

Yes. The TS-X is precision-engineered as a Flygt pump seal replacement, manufactured to match exact dimensional tolerances and operating requirements of Flygt submersible pump models. This ensures reliable sealing, leak prevention, and long service life.

4. What are the typical applications for the TS-X seal?

The TS-X seal is commonly used in submersible Flygt pumps handling wastewater, sludge, sewage, and abrasive fluids. As a high-performance Flygt pump seal, it delivers consistent operation, enhanced wear resistance, and reduced maintenance downtime in municipal and industrial environments.

5. What size options are available for the TS-X mechanical seal?

The TS-X mechanical seal is available in multiple shaft sizes, including 20 mm, 22 mm, 25 mm, 28 mm, 30 mm, and 35 mm, with precise dimensional specifications to ensure compatibility across various Flygt pump models.

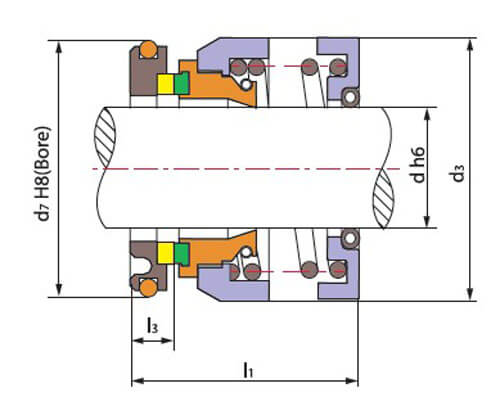

|

Seal size |

d3 |

d 7 |

l 1 |

l 3 |

|

20 |

42.5 |

55.5 |

36.5 |

11.0 |

|

22 |

47.0 |

45.5 |

32.6 |

9.0 |

|

25 |

54.0 |

50.5 |

38.6 |

10.0 |

|

28 |

54.0 |

50.5 |

38.6 |

10.0 |

|

30 |

54.0 |

50.5 |

38.6 |

10.0 |

|

35 |

62.0 |

60.5 |

39.8 |

11.0 |

### **Applications of Flygt Pump Seal**

Flygt pump seals are engineered to provide **reliable sealing solutions** for submersible pumps, ensuring optimal performance and durability in various **demanding applications**. These seals are specially designed to withstand **extreme temperature**, high pressure, and aggressive media, making them ideal for industrial and municipal pumping systems.

#### **Key Applications of Flygt Pump Seals:**

1. **Wastewater Treatment Plants**

- Used in **Flygt submersible pumps** for sewage and sludge handling

- **Upper and lower seals** prevent leakage and ensure long-term reliability in harsh environments

2. **Mining and Slurry Handling**

- Ensures effective sealing in abrasive and corrosive slurries

- Enhances pump efficiency in dewatering and slurry transport applications

3. **Industrial Water and Process Fluids**

- Provides leak-proof operation in process pumps handling chemicals and high-viscosity fluids

- Used in cooling systems and **centrifugal pumps** for industrial applications

4. **Stormwater and Flood Control**

- Protects **Flygt submersible pumps** used for draining excess water in flood-prone areas

- Increases the reliability of drainage and stormwater management systems

5. **Agriculture and Irrigation**

- Ensures proper functioning of submersible pumps in irrigation and water distribution

- Prevents contamination and increases seal life in **demanding applications**

6. **Marine and Offshore Applications**

- Used in seawater pumping systems to prevent corrosion and leakage

- Enhances performance in desalination and offshore drilling operations

7. **Power Generation and Cooling Systems**

- Ensures efficient sealing in cooling pumps used in power plants

- Withstands **extreme temperature** and high-speed operating conditions